In the industrial machinery sector, Dekuma constructs their reputation on the principle of precision engineering. Their identity as a creator of custom rubber machine solutions is deeply tied to their technical choices. They select high-grade components to build a foundation of reliability for their clients, which is a critical factor for production-dependent businesses.

The Role of Advanced Control Systems

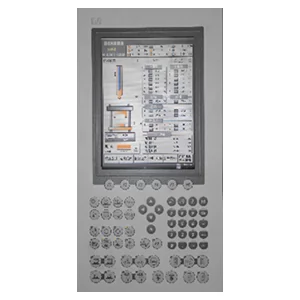

A core feature of any Dekuma custom molding machine is its control system. They utilize a specialized industrial computer and software to manage operations. This technological approach allows for exact command over the molding process. For a business that requires a specific custom rubber machine, this level of control is indispensable for achieving consistent product quality and maintaining repeatable production cycles without unexpected interruptions.

Component Quality for Operational Integrity

The hydraulic performance of a Dekuma custom molding machine is governed by original German proportional valves. These components manage flow rate, pressure, and direction. The use of these valves, alongside world-famous sealing parts, helps ensure machine movements are smooth and free from leaks. This technical specification is vital for any custom rubber machine that must operate with precision and avoid costly downtime due to component failure or fluid leakage.

An integral part of Dekuma’s engineering philosophy is the use of cutting-edge control software and globally renowned components. They plan to construct a dependable custom molding machine using this strategy. By prioritizing the quality of internal systems, businesses that need long-lasting and accurate bespoke rubber machines get a substantial operational advantage that allows for efficient and continuous manufacture.