As electric vehicles (EVs) continue to grow in popularity, driven by rapid advances in automotive technology and stronger environmental awareness, the demand for lightweight and durable materials has become increasingly important. DEKUMA recognizes this trend and offers innovative solutions in this space. Thermoplastic Vulcanizate (TPV), which combines the flexibility of rubber with the processing advantages of plastic, is now widely used in EV fluid management systems. DEKUMA’s expertise in processing TPV ensures that manufacturers can meet the evolving needs of the EV market efficiently and effectively.

DEKUMA’s Innovative TPV Extrusion Line

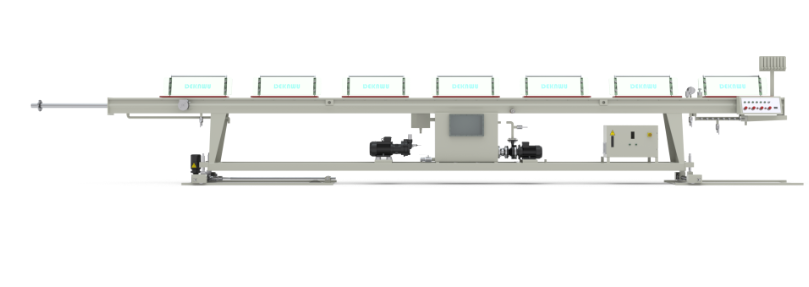

To meet this demand, DEKUMA developed a dedicated TPV extrusion line for EV hose production. This reliable line adopts a three-layer structure: a TPV inner layer, knitted reinforcement (polyester or aramid), and a TPV outer coating. This innovative design enables efficient output of knitted composite hoses, as well as double-layer and single-layer variants. The line is engineered for high precision and stable multi-layer control, ensuring reliable performance in continuous production.

DEKUMA’s commitment to advancing technology is evident in its use of the conical screw PVC pipe extruder. This machinery plays a vital role in enhancing the efficiency and quality of the TPV extrusion process. The conical twin screw pipe extruder PVC further complements this technology, allowing for optimal mixing and processing of materials, which is critical in producing high-quality hoses for EV applications.

The Importance of Material Innovation in EVs

As the automotive industry shifts towards sustainability, the role of advanced materials like TPV cannot be overstated. The lightweight nature and durability of TPV significantly contribute to the overall efficiency of electric vehicles. By utilizing innovative extrusion lines, manufacturers can produce components that meet the rigorous demands of EV fluid management systems.

Conclusion

DEKUMA is at the forefront of innovation with its dedicated TPV extrusion line, which incorporates advanced machinery such as the conical screw PVC pipe extruder and the conical twin screw pipe extruder PVC. As the demand for lightweight and durable materials continues to rise, DEKUMA’s contributions to the EV industry position it as a leader in the evolving landscape of automotive technology.